| Datapool |

Professional SQL database for central storage, management and distribution of workpiece data |

|

| PeriGrind |

Peripheral grinding rim with extended programming syntax (PeriGrind) |

|

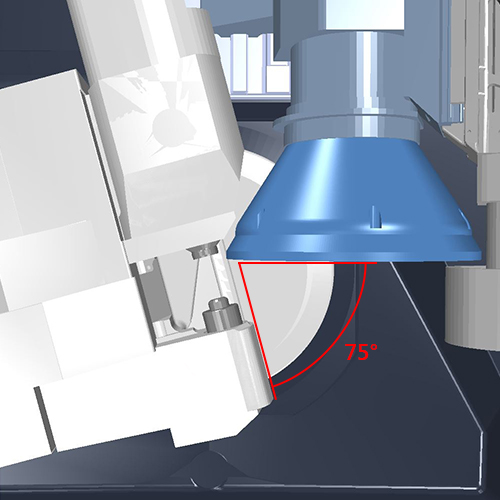

| Chamfering for Leo Peri |

Highly productive chamfer grinding of K-Lands of more than 15° |

|

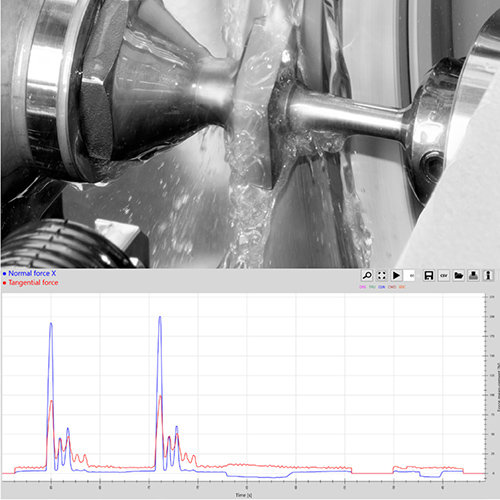

| Force measurement |

2D force measuring system for normal and tangential forces for process definition, optimization and control |

|

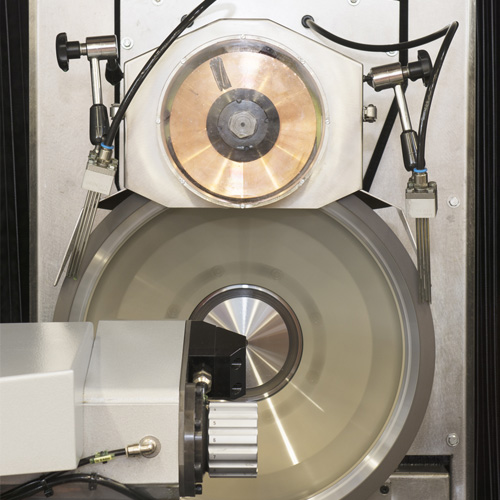

| Re-clamping B1 parts | Multiple clamping |

Dom Plus: Grinding a second chamfer

Evo: Grinding of a workpiece in multiple clamping operations |

|

| Adaptive infeed |

In addition to the constant feed, the grinding force is specified here |

|

| Programming station |

Offline programming environment on the PC workstation with identical user interface as on the machine |

|

| AGS 3D simulation |

Interactive 3D machining simulation for the creation of complete grinding programs |

|

| Advanced 3D simulation |

Advanced 3D simulation offers significant improvements in visualization and, among other things, displays the entire grinding area |

|

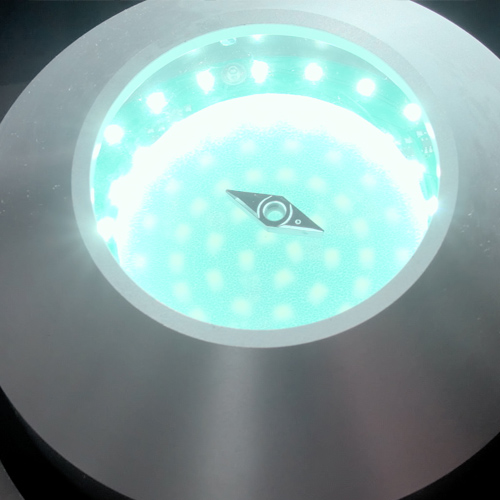

| AGP-Iso |

Graphical creation of grinding programs for ISO indexable insert |

|

| FRP - Free Reference Plane |

Programming command with which the entire FRP programming coordinate system can be set as required |

|

| Edge Grinding |

Programming command with which a curve with the grinding wheel edge ECH can be ground |

|

| Spline |

Programming command that can be used to grind a general SPLINE curve using predefined points |

|