Die Bearbeitung von Löchern und konkaven Features in harten und spröden Materialen ist beschwerlich, teuer und zeitintensiv? Nicht mit der revolutionären Neo Laser von Agathon! Mit einer 100-fach höheren Abtragungsrate im Vergleich zum Schleifen und der Fähigkeit, Löcher mit definierten Konuswinkeln zu lasern, ist die Neo die bahnbrechende Lösung für die Herstellung von Löchern und Mulden in Superhartstoffen.

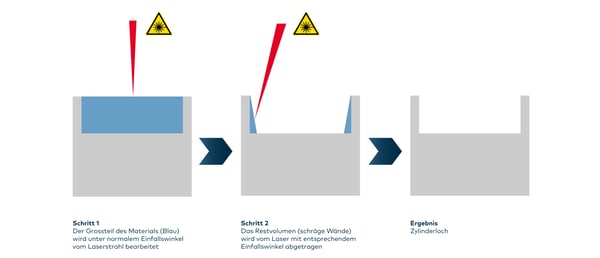

Der zweistufige LaserDrill-Prozess

- Schritt: Ein Konus wird aus dem Werkstück abgetragen (siehe Grafik 1, Bild links), die Oberfläche wird nahezu orthogonal bestrahlt. Die entstehenden Wände sind nicht senkrecht.

- Schritt: Die Wände des Konus werden unter einem spezifischen Einfallswinkel vom Laser bearbeitet, sodass der Konuswinkel vollständig abgetragen werden kann. Dafür wird das Werkstück durch die mechanischen Achsen der Maschine umpositioniert (siehe Grafik 1, Bild Mitte).

Grafik 1: Schematischer Schnitt vom Werkstück. In Blau die Volumen, die bearbeitet werden. Abb. links: Schritt 1 – Abtragung Konus aus Werkstück. Abb. Mitte: Bearbeitung der Wände des Konus mit Laser. Abb. rechts: fertiges Ergebnis.

Zwecks eines möglichst effizienten Prozesses wird das Loch typischerweise in mehrere Scheiben mit rund 1 mm Dicke unterteilt. Der zweistufige Prozess erfolgt auf jeder einzelnen Scheibe. Dadurch entsteht am Ende der Bearbeitung einer Scheibe eine zylindrische Senkung. Dies wird bis zur gewünschten Tiefe mehrmals wiederholt. Dadurch wird vermieden, dass ein Teil der Laserenergie von den Wänden absorbiert und in Wärme umgewandelt wird.

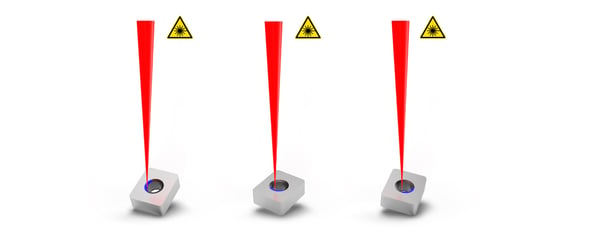

Der zweite Schritt ist im Detail komplexer, da die schräge Wand um den ganzen Perimeter des Lochs liegt. Das im zweiten Schritt abzutragende Volumen ist ringförmig und wird in Segmente unterteilt, um diese einzeln zu bearbeiten. Dies geschieht, nachdem das Werkstück umpositioniert wurde (siehe Grafik 2). Dieser komplexe Prozess erfolgt jedoch mit wenigen Parametern, so dass es den Maschinenbediener nicht tangiert.

Grafik 2: In Blau dargestellt ein Segment (1/4 des kompletten Rings), das unter einem Winkel bearbeitet wird. Im Bild zu sehen sind drei der vier Schritte im Bearbeitungsprozess der Segmente. Das Werkstück wird für jedes Segment umpositioniert.

Der zweistufige Prozess macht es möglich, dass Löcher in guter Qualität besonders schnell in Platten abgetragen werden. Dazu einige Angaben zur möglichen Bearbeitungsdauer:

|

Bohrung |

Werkstück |

Zeitdauer |

|

Ø4mm Zylinderloch |

4.8 mm Hartmetall |

12 min |

|

Ø4mm Zylinderloch |

4.8 mm solid CBN |

4 min |

|

M4 Schraubenloch |

4.8 mm Hartmetall Platte mit 0.8 mm PKD |

17 min |

|

M3 Schraubenloch |

4.8 mm Hartmetall Platte mit 0.8 mm PKD |

6 min |