Welcome to Grinding Hub 2024

At the Grinding Hub in Stuttgart (Hall 9, Booth 9A15), you can experience our new Evo Quinto grinding machine, which sets new standards, up close and in action. It builds on the existing Evo platform and offers you not only an outstanding machine, but also a complete solution package that can be individually customized. Agathon not only offers machines that make your day-to-day work easier, but also services that help you achieve your goals with ease. Our services in the areas of Operation, Education and Application complement each other, because our success is your success. Care360 - services from professionals for professionals.

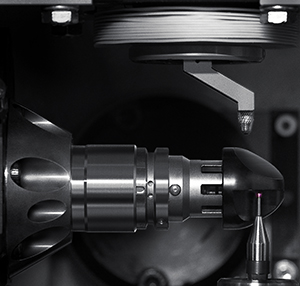

Are you ready for a revolutionary improvement in the machining of superhard indexable inserts? The PowerGrind PoG2.0 generator from Agathon redefines grinding performance. Experience a unique combination of benefits: Increased stock removal and improved final quality. With Agathon, you can achieve perfection with every grind - efficient, precise and unbeatable.

Discover Leo2, proven technology with new, future-oriented control. Your access to groundbreaking innovations in manufacturing. With revolutionary technology and unrivaled expertise, it points the way to a smarter, more efficient future.

Our exhibition highlights

Read more

Read more

Read more

Process optimization with future-proofing

Benefit from the latest technology with minimal additional effort. Introducing PowerGrind 2.0: Increase removal rates and productivity! Read our blog!

With advanced features and intuitive controls, PowerGrind 2.0 redefines grinding technology and delivers unparalleled efficiency and performance. PowerGrind 2.0 increases dressing efficiency and stabilizes the spark gap.

Simplified service and maintenance

Discover Leo2: Your access to ground-breaking innovations in manufacturing. With revolutionary technology and unrivaled expertise, Leo2 is leading the way to a smarter, more efficient future.

Benefit from our proven technology with new, future-oriented controls. With Leo2 you install state-of-the-art technology, fully backwards compatible and you also minimize your energy consumption. Invest in the future now!

20% reduction in cycle times

Evo Penta with new application: ball track milling cutter. Thanks to the large 400 mm diameter grinding wheel and in-process dressing, cycle times have been reduced by 20% compared to previous processes. Read more in our flyer.

The three most important functions and advantages of the new application are:

1. Individual measurement of the tip surface before grinding

2. Ingenious clamping correction

3. Measurement of the finished ball end mill in the clamped state with the 3D measuring probe

Meet our consultants in person at the stand

Book an appointment with us!

Do you want efficient programming of your grinding machines? Experience how easy our machines can be programmed or integrated into an MES network!

Ghost shift? Yes, with our pallet stacker, large series can be processed and monitored efficiently and autonomously.

Clean clamping and monitoring of indexable inserts and grooving inserts, core elements for productivity ... all-round service package or subscription increase availability!

Pioneering innovation and a head start through precision since 1918

Since its foundation in 1918, Agathon has been a solid family business with technological leadership and a clear focus on innovation. As the world's leading manufacturer of high-tech grinding and laser machines as well as precision parts for machine, tool and mold making, we offer high-precision, modern and pioneering technologies. Our consistent and young product portfolio is supported by our headquarters in Bellach, Switzerland and our subsidiaries in Germany, North America, China and India. With around 290 employees, we are always close to our customers. Our excellent customer service, an application center in the heart of Europe and a global network of representatives guarantee our customers worldwide technical support, training and advice for comprehensive solutions. Our motto is not "Strive for the best" for nothing.