Dom Plus - Geringe Kosten pro Werkstück

Leistungsstarke Direktantriebe auf X,-Y- und C-Achse

Hohe Flexibilität und Produktions-Autonomie

Dom Plus - attraktive Optionen

Dom Plus - Hochpräzises 4-Achsen-Schleifzentrum zur Bearbeitung von Wendeschneidplatten am Umfang mit 2 Schutzfasen durch Umspannen

Bedienung

sowie Werkzeuge und Programmierung sind zu den anderen Agathon Maschinen weitgehend kompatibel

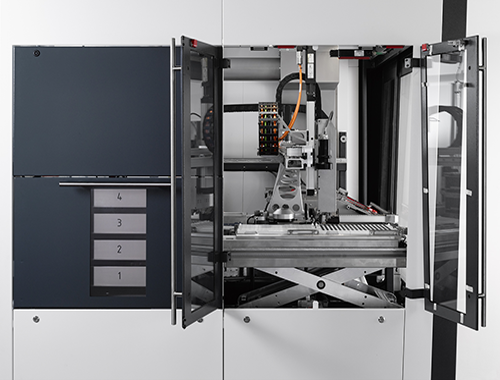

Handling

Dynamisches, voll integriertes 3-Achsen Linearhandling mit 180° drehbarem Ladegreifer für flexible Handling- Abläufe und zum Schleifen einer 2. Fase. Das Paletten-Ablagesystem bietet 4 Einschübe und 8 bis 12 Paletten.

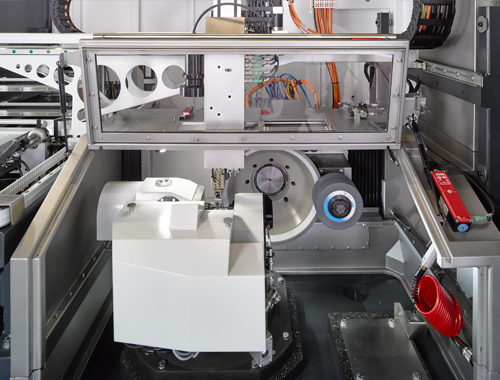

Gekapselter Schleifraum

mit Schleiftopfdurchmesser 350 mm und leistungsoptimierte Direktantriebe auf X-, Y- und C-Achse Es sind Inprozess- oder externe Abrichtkonzepte möglich.

Steuerung

mit modernster Technologie

Das Dom Plus Konzept

Dom Plus - die Grundmaschine

- Übersichtliche Konstruktion mit bester Einsicht und Dachmontagemöglichkeit für Peripheriegeräte

- 180° drehbarer Ladegreifer für flexible Handling- Abläufe und zum Schleifen einer 2. Fase

- Palettenablagesystem mit 4 Einschüben und 8 bis 12 Paletten

- Leistungsstarke Direktantriebe auf X-, Y- und C-Achse

- Inprozess- oder externe Abrichtkonzepte möglich

- Kompakter, gekapselter Schleifraum

- Schleiftopfdurchmesser 350 mm

- Konstruiert nach neusten Eco-Designgrundsätzen

- Werkzeuge, Bedienung und Programmierung sind zu den anderen Agathon Maschinen weitgehend kompatibel

Technische Daten

| Anzahl Paletten | 8 (12) |

| Ø Schleiftopf | 350 mm |

| Abmessungen (L x B x H) | 2.75 m x 2.10 m x 2.22 m (mit Leuchte 2.60 m) |

| Arbeitshöhe Schleifraum | 950 mm |

| Gewicht | 5300 kg |

| Schwenkbereich C-Achse | -90° bis +45° |

| OD | IC | max. 60 mm | min. 3.96 mm |

| Werkstück-Spannweg | 23.5 mm |

| Materialien | Hartmetall, Cermet, Keramik, CBN, PKD |

Benutzerfreundlichkeit

- Hervorragende Einsicht und Zugänglichkeit dank ergonomischem Design

- Durchgängige Agathon Bedienungsphilosophie und Software

- Einzigartige, domänen-spezifische Programmiersprache für Wendeschneidplatten

- Optionale Software zur einfachen Erstellung von Programmen für ISO-Wendeschneidplatten (AGP-Iso)

- Einfaches Reteach

- Schnell zu reinigen dank gekapseltem, kompaktem Schleifraum

- Wartungsfreundlich

- Umfangreiches Schulungsangebot für Programmierung, Bedienung, Unterhalt

Ausgewählte Optionen

- Vision-System für Teileausrichtung und Spoterkennung

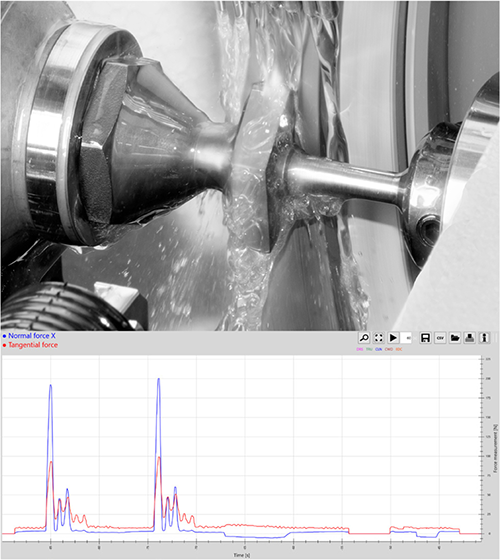

- 2D-Kraftmessungssystem für Normal- und Tangentialkraft zur Prozessdefinition, Optimierung und Kontrolle

- Grafische Erstellung von Programmen für ISOWendeschneidplatten (AGP-Iso)

- Umfangreiche Möglichkeiten bei Connectivity und Datamanagement

Dom Plus - Herausragende Vorteile

Hohe Autonomie und Flexibilität

- Standardmässig mit Palettenablagesystem mit 4 Einschüben

- Pro Einschub 2 bis 3 Palettenplätze

- Alle Paletten eines Einschubs simultan von Linearhandling erreichbar

- 180° drehbarer Ladegreifer für 2. Fase und weitere Handling-Abläufe

- Hochauflösendes Vision-System

- Hohe Prozessstabilität Geringe Kosten pro Werkstück

Geringe Kosten pro Werkstück

- Kurze Nebenzeiten durch agiles Handling und internes Abrichten

- Einheitliche, kompatible Agathon-Werkzeuge

- Schneller Produktwechsel durch Offline-Programmierung und grafische Simulation

- Reduzierter Energiebedarf durch konsequentes Eco-Design

- Wartungsarme Komponenten

Höchste Verfügbarkeit

- Modernste, wartungsarme Antriebe

- Kurze Umrüstzeiten

- Designed and manufactured in Switzerland

- Schneller, kompetenter und effizienter Tele- und Service vor Ort