Evo Penta

Unübertroffene Produktivität und Flexibiliät für komplexe Geometrien

Evo Penta

Geringe Kosten pro Werkstück

Evo Penta

Perfekte Optionen für alle Anwendungen

Evo Penta

Die neuesten Applikation der Evo Penta: Der innovative Kugelbahnfräser

Evo Penta - Hochpräzises 5-Achsen-Schleifzentrum zur Bearbeitung von Wendeschneidplatten mit komplexen Geometrien

Umfangreiche Möglichkeiten

bei Connectivity und Data Management.

Werkzeuge, Bedienung und Programmierung

sind zu den anderen Agathon Maschinen weitgehend kompatibel.

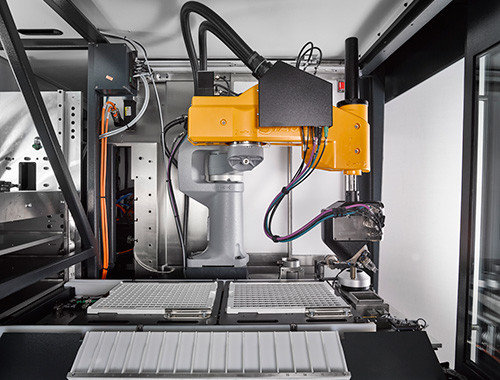

Handling

• Agiler SCARA Roboter

• Zwei Paletten im Arbeitsraum für Trennung von Roh- und Fertigteilen

Leistungsstarke Direktantriebe auf X-, Y- und C-Achse

• Erweiterte Fahrbereiche und Schwenkwinkel

• Bewährter Penta Werkstück-Spindelstock

• Schnelle, dauerfeste B-Achse

• Interne und externe Abrichtgeräte kombinierbar

• Schleiftopfdurchmesser 400 mm

Unsere neuste Applikation auf der Evo Penta

Evo Penta im Detail

Evo Penta - die Grundmaschine

- Bewährte Konstruktion mit guter Zugänglichkeit

- Erweiterte Fahrbereiche und Schwenkwinkel für die Fertigung von komplexen Teilen ohne Umspannen

- Bewährter Penta Werkstück-Spindelstock

- Leistungsstarke, wartungsarme Direktantriebe auf X-, Y- und C-Achse

- Interne und externe Abrichtgeräte kombinierbar

- Schleiftopfdurchmesser 400 mm

- Agiler 4-achsiger SCARA Roboter

- Schleifraum vom Handlingraum getrennt

- Zwei Paletten im Arbeitsraum für Trennung von Roh- und Fertigteilen

Technische Daten

| Anzahl Paletten | max. 16 |

| Ø Schleiftopf | 400 mm |

| Abmessungen (L x B x H) | 3.06 m x 2.10 m x 2.22 m (mit Leuchte 2.60 m) |

| Gewicht | 6500 kg |

| Schwenkbereich C-Achse | -140° bis +140° |

| OD | IC | max. 50 mm | min. 3.96 mm |

| Werkstück-Dicke | 29 mm |

| Materialien | Hartmetall, Cermet, Keramik, CBN, PKD |

Benutzerfreundlichkeit

- Werkzeugspindelstock nahe an Maschinenfront für besseren Zugang

- Durchgängige Agathon Bedienungsphilosophie und Software

- Einzigartige, domänen-spezifische Programmiersprache für Wendeschneidplatten

- Einfaches Reteach

- Erprobte, perfekt integrierte Automation

- Umfangreiches Schulungsangebot für Programmierung, Bedienung, Unterhalt

Ausgewählte Optionen

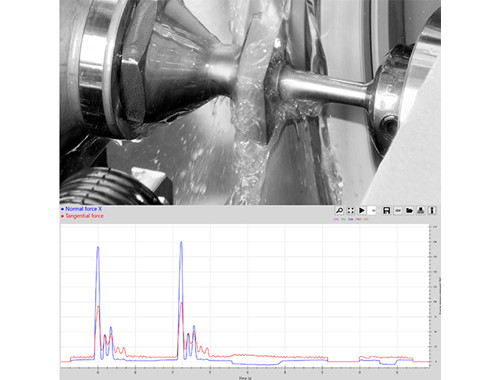

- Elektro-erosives Konditionierverfahren (PowerGrind)

- Robuste U-Achse für Inprozess Reinigen, Schärfen und Profilieren

- 2D-Kraftmessungssystem für Normal- und Tangentialkraft zur Prozessdefinition, Optimierung und Kontrolle

- Umfangreiche Möglichkeiten bei Connectivity und Data Management

- Vision-System für Teileausrichtung und Spoterkennung

- 3D-Messtaster: Zusätzlicher X-Y-Z-Messtaster für die Vermessung von Werkstückmerkmalen im gespanntem Zustand

Evo Penta - Herausragende Vorteile

Geringe Kosten pro Werkstück

- Kürzere Schleifzeiten dank sehr hohen Abtragsraten

- Kurze Nebenzeiten durch agiles Handling und internes Abrichten

- Komplettbearbeitung ohne Umspannen

- Einheitliche, kompatible Agathon-Werkzeuge

- Schneller Produktwechsel durch Offline-Programmierung und grafische Simulation

- Bis 50% Zykluszeitreduktion mit PowerGrind

- Wartungsarme Komponenten

Flexibilität bei Material, Prozess und Geometrie

- Vergrösserte Schwenkwinkel und Fahrbereiche für deutlich mehr schleifbare Geometrien

- Beidseitige Bearbeitung ohne Umspannen

- 5 Achsen für breites Spektrum von Teilen und Geometrien

- Freie Kombination verschiedener Abrichtverfahren

- Von IC 3.96 mm bis OD 50 mm grösstmöglicher Einsatzbereich

- Sämtliche gängigen Wendeschneidplatten-Materialien

Höchste Verfügbarkeit

- Hohe Autonomie mit 16-fachem Palettenspeicher

- Modernste, wartungsarme Antriebe

- Kurze Umrüstzeiten

- Designed and manufactured in Switzerland

- Schneller, kompetenter und effizienter Tele- und Service vor Ort